SS-PREP® GH4169 Alloy Powder by Sino-Euro

1. Introduction

GH4169 powder (Inconel 718) is a precipitation-hardened Nickel-Chromium-iron based alloy, which includes Niobium and Molybdenum elements. It possesses excellent comprehensive properties within a temperature range of -253℃ to 700℃. Below 650℃, The yield strength of GH4169 alloy is among the highest compared to other wrought superalloys, showcasing outstanding resistance to fatigue, radiation, oxidation, and heat corrosion. Additionally, it offers favorable processing characteristics, weldability, and long-term microstructural stability. It is primarily used as a major material for compressor disks, compressor shafts, compressor blades, turbine disks, turbine shafts, casings, fasteners, and other structural components.

2. Powder Characterization

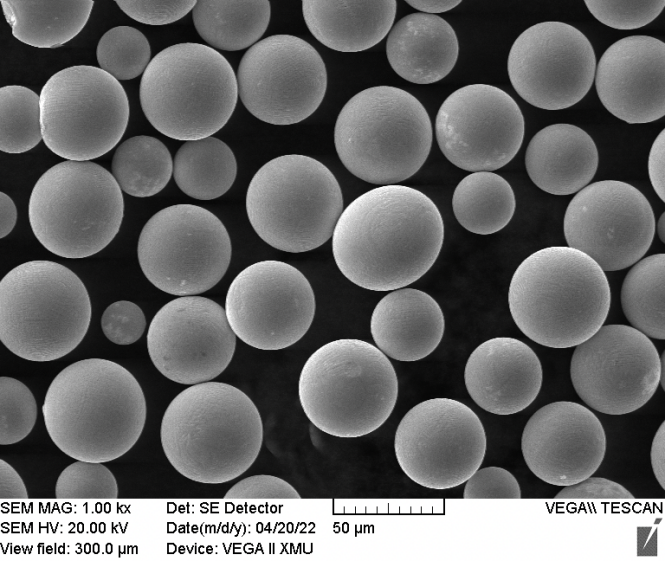

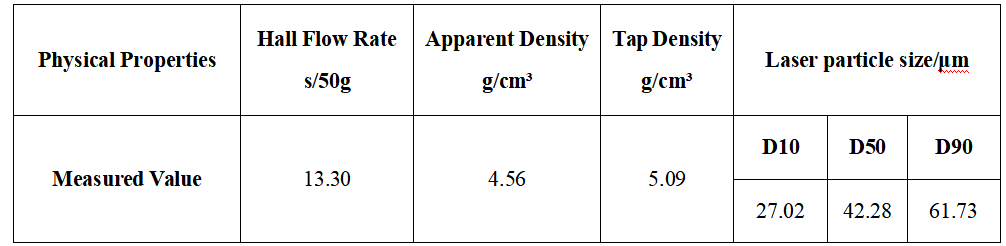

Sino-Euro utilizes the advanced Super Speed Plasma Rotating Electrode Process (SS-PREP®) to produce SS-PREP® alloy powder, which exhibits exceptional physical properties. As illustrated in Figure 1, the SS-PREP®-GH4169 alloy powder with a particle size range of 15-53 µm demonstrates high sphericity and an extremely low hollow fraction. The measured properties of the alloy powder are summarized in Table 1: the Hall flow rate is recorded at 13.30 s/50g, while the apparent density is measured at 4.56 g/cm³ and the tapped density at 5.09 g/cm³.

Figure 1 SEM morphology of SS-PREP®-GH4169 (15-53µm)

Table 1 Properties of SS-PREP®-GH4169 (15-53µm) powder

3. Printing Characterization

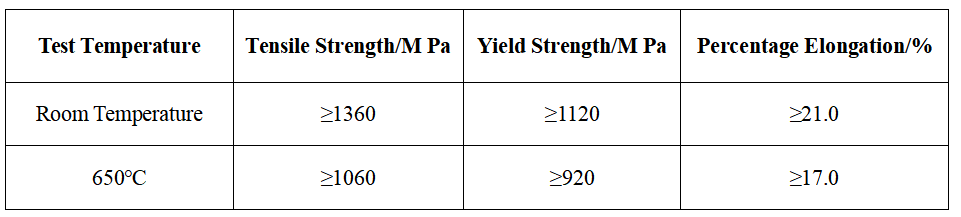

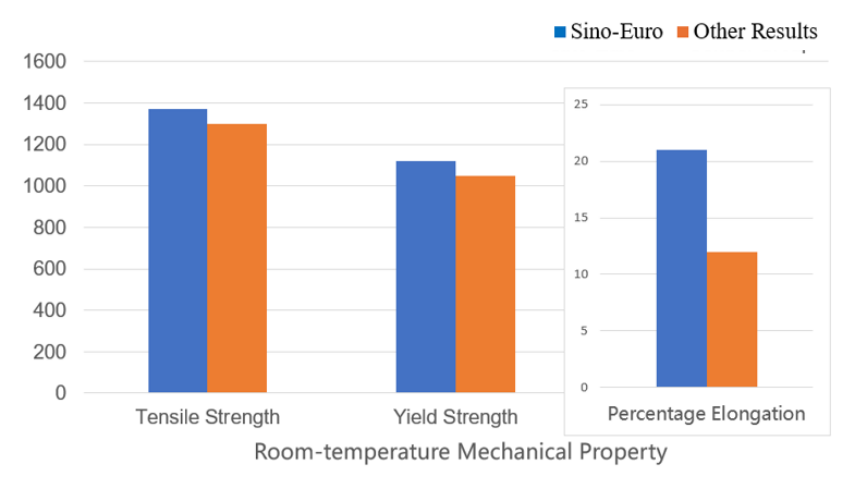

The GH4169 alloy used in additive manufacturing is prone to residual stress, the formation of detrimental phases, elements segregation, and other issues that can hinder components from achieving required industrial standards. However, by employing the SS-PREP®-GH4169 alloy powder produced by Sino-Euro and optimizing the process, it is possible to markedly improve the performance of the fabricated parts. Table 2 presents the performance test results for parts produced using SS-PREP®-GH4169 alloy powder via selective laser melting, showing that these components possess outstanding mechanical properties. As depicted in Figure 2, when compared to other results (with performance data obtained from literature research), the room temperature mechanical properties of parts fabricated with SS-PREP®-GH4169 alloy powder demonstrate enhancements of 3.50% in tensile strength, 6.07% in yield strength, and a remarkable 68% increase in elongation.

Table 2 Mechanical properties of SS-PREP®GH4169 powder prints

Figure 2 Comparison of mechanical properties of SS-PREP®-GH4169 alloy at room temperature with other results

Company Introduction

Xi’an Sino-Euro Materials Technologies Co., Ltd (Sino-Euro), a subsidiary of the Northwest Institute for Non-ferrous Metal Research, specializes in high-end metal spherical powder and powder metallurgy parts of the production and service of the national specialized, refined, peculiar and innovative “little giant” enterprise. Sino-Euro was established in 2013 with a registered capital of 180 million RMB. Through making further innovation on the basis of absorbing advances in overseas science and technology, Sino-Euro has established the internationally advanced and domestically first-class “SS-PREP Disk® powder” (Supreme-speed Plasma Rotating Electrode Process), as well as the first domestic SS-PREP superalloy disks and hot isostatic pressing (HIP) short process industrial production line. Sino-Euro possesses the capacity to produce 1,500 tons of metal spherical powder and 2,000 powder metallurgy parts annually. The company is committed to the development, production, import and export trade of titanium alloys, superalloys, metal spherical powders, and powder metallurgy parts.

Major businesses:

The businesses have a presence in more than 20 countries and regions. The products include titanium alloy TC4 (Ti6Al4V), TC11, TC18, TC17, TC21, TA15, Ti60, Ti65, Ti80, Ti2AlNb, TiAl, etc. Superalloy GH4169 (Inconel718), GH4099, GH3230, GH3536, GH3625, GH5188, EP741NP (FGH4097), Mar-M247, K477, and 304, 316L, 17-4PH, 18Ni300 and other special steel 100 Multiple brands. These products mainly applied in aerospace, additive manufacturing (3D Printing), biomedical fields.

The metal spherical powder comprehensively covers laser selective melting forming (SLM, 15-53μm), electron beam selective melting forming (EBM, 53-106μm), laser melting deposition forming (LENS, 50-150μm), hot isostatic pressing (HIP, 75-250μm) and Thermal Spray. 22-212μm) and other metal 3D printing and near net shape forming technology.

Tel: 029 8626 1802

E-mail: market2@c-semt.com

Address: No.45, 2nd Fengcheng Road, Xi’an, Shaanxi, China

Website: www.c-semt.com

Previous: None

Navigation

Follow Us